The first steps made in the field of connecting local power grids showed that the interconnections between power systems should have sufficient transmission capacity and be able to distribute electrical energy over distances of hundreds of kilometers.

The crucial issues related to long distance energy transmission were addressed at the beginning of the twentieth century. By this time two main directions in electrical energy distribution had been developed – through overhead transmission lines and underground cable lines. Further advancements in both these directions revealed that overhead lines and cable lines are different in terms of the possible applications due to their respective structural features.

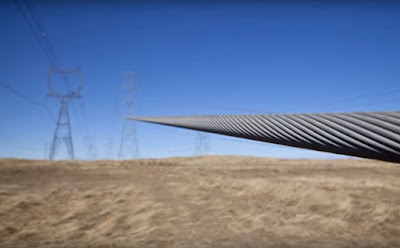

When it comes to overhead transmission lines, atmospheric air serves as the main dielectric medium insulating wires from the ground, surface structures, and from the other phase wires between supports. This makes it possible to relatively easily raise the transmission line voltage and capacity by increasing electrically safe distances between wires and the ground or other objects such as buildings (the wire insulation grade should simultaneously go up). At the same time, longer distances between wires and the ground lead to utilizing a larger territory and above-ground space for installing overhead lines.

Cable lines are made of current conductors, the whole length of which is covered with insulating and protective sheaths, and the thickness of which is a few times less than the safety margin of overhead lines. The thin insulation of cable lines allows for efficient space usage during line installation. However, until the end of the twentieth century there was no technology available for laying long-distance cable lines with voltage over 40 kV; thus, the transmission capacity was limited. Another thing to bear in mind is that large electrical capacity of AC cable lines with a voltage of 110 kV and higher considerably limits their length to a few dozens of kilometers due to overvoltage occurring during operation.

AC cable lines are typically used as a local means of distributing electricity among consumption points when the construction of overhead lines is deemed impractical. Cable lines are made into electricity distribution systems in cities and other residential areas, manufacturing enterprises and housing. The usage of cable lines for interconnections has only been practical in the context of high-voltage power direct current, which removes the limits on the length of interconnections. DC cable lines have been utilized for asynchronous connection of power supply systems divided by large water bodies, e.g. the English Channel, the Baltic Sea, the Adriatic Sea, and the Tyrrhenian Sea.

Overhead transmission lines are the most widespread since their installation cost, related to their transmission capacity, is much lower than that of cable lines; in addition, overhead lines are easier to install and maintain. Summing up, the fact that overhead lines are the ones used for interconnections is explained by their ability to transmit electricity over long distances with high transmission capacity.

http://news.chivindo.com/377/role-of-interconnections-in-long-distance-energy-transmission.html

http://news.chivindo.com/377/role-of-interconnections-in-long-distance-energy-transmission.html

The crucial issues related to long distance energy transmission were addressed at the beginning of the twentieth century. By this time two main directions in electrical energy distribution had been developed – through overhead transmission lines and underground cable lines. Further advancements in both these directions revealed that overhead lines and cable lines are different in terms of the possible applications due to their respective structural features.

When it comes to overhead transmission lines, atmospheric air serves as the main dielectric medium insulating wires from the ground, surface structures, and from the other phase wires between supports. This makes it possible to relatively easily raise the transmission line voltage and capacity by increasing electrically safe distances between wires and the ground or other objects such as buildings (the wire insulation grade should simultaneously go up). At the same time, longer distances between wires and the ground lead to utilizing a larger territory and above-ground space for installing overhead lines.

Cable lines are made of current conductors, the whole length of which is covered with insulating and protective sheaths, and the thickness of which is a few times less than the safety margin of overhead lines. The thin insulation of cable lines allows for efficient space usage during line installation. However, until the end of the twentieth century there was no technology available for laying long-distance cable lines with voltage over 40 kV; thus, the transmission capacity was limited. Another thing to bear in mind is that large electrical capacity of AC cable lines with a voltage of 110 kV and higher considerably limits their length to a few dozens of kilometers due to overvoltage occurring during operation.

AC cable lines are typically used as a local means of distributing electricity among consumption points when the construction of overhead lines is deemed impractical. Cable lines are made into electricity distribution systems in cities and other residential areas, manufacturing enterprises and housing. The usage of cable lines for interconnections has only been practical in the context of high-voltage power direct current, which removes the limits on the length of interconnections. DC cable lines have been utilized for asynchronous connection of power supply systems divided by large water bodies, e.g. the English Channel, the Baltic Sea, the Adriatic Sea, and the Tyrrhenian Sea.

Overhead transmission lines are the most widespread since their installation cost, related to their transmission capacity, is much lower than that of cable lines; in addition, overhead lines are easier to install and maintain. Summing up, the fact that overhead lines are the ones used for interconnections is explained by their ability to transmit electricity over long distances with high transmission capacity.

Source (Russian language): http://energetika.in.ua

About KEP

KEP (KharkovEnergoPribor Ltd.) produces high voltage testing equipment, including portable testing instruments and cable test vans, for the world’s leading power engineering companies. The KEP’s product range includes solutions for cable tracing, cable diagnostics and fault locating, testing high voltage instruments and safety gear, and oil dielectric testing.

We at KEP believe that our main task is to translate the customer’s requirements into the top-quality product, combining cutting-edge technology with fundamental high voltage testing principles.

Alexei Tiatiushkin

Marketing manager

KharkovEnergoPribor Ltd.

marketing@keppowertesting.uk

Comments

Post a Comment