Eddy Current

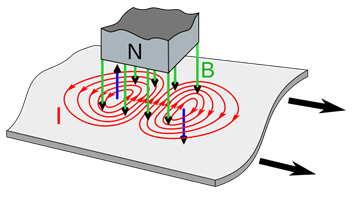

According to Faraday's and Lenz's law, when varying magentic field is subjected to a conducting loop, emf of different magnitude is induced in the conducting loop. The potential differential of the induced emf cause current to flow in the conducting loop. The current set up by this mechanism is called the eddy current. The eddy current flows in a closed loop, perpendicular to the magnetic field.The eddy current is also called Foucault's current. The eddy current circulates in the conducting loop like swirling eddies in a stream. The eddy current can be harmful in the case of electrical machines, however eddy current can be benefecial as well.

The eddy current cause undesired heating in electrical machines like transformer, induction motor and generator and, thus it lowers the efficiency of the electrical machine. However, there are numerious application where eddy current principle is used. The eddy current is used in various inductrial processs like induction heating, braking, welding. The eddy current is also used in finding the defect in the materials. Let us understand how the eddy current cause power loss in the transformer.

Eddy Current Loss in Transformer

When the primary of transformer is fed alternating ac voltage, the varying magnetic field is set up in the magnetic core. The magnetic flux gets linked to both the primary and secondary winding of the transformer.

However, the varying magnetic field also induces voltage in the conductive magnetic core and cause eddy current to flow in the magnetic core. The eddy current set up in the magnetic core depends on the resistivity of the material, frequency of the excitaion source, peak value of magnetic field and thickness of the material. The resistivity of the core can be increased by use of CRGO grade steel. The eddy current loss in the core can be found by following mathematical expression.

Where, Ke = Constant - Its value depends on the resistivity of material

f = frequency of the exciatation source

Bm = Peak Value of magnetic field

t = Thickness of the materia

Therefore, it is necessary to reduce the eddy current loss to ameliorate efficiency of the transformer. In order to reduce the eddy current loss, the core is formed by stacking thin plates called laminations. The each plate is insulated from each other to hinder the current flowing from one sheet to another. Thus, the eddy current confined to a very small area of each plate.

Properties of Eddy Currents

- These are induced only inside the conducting materials.

- These are distorted by defects such as cracks, corrosion, edges etc.

- Eddy currents attenuate with depth with highest intensity present at the surface.

- These properties lead to numerous applications of eddy currents in power, aerospace and petrochemical industries for detecting metal cracks and damages.

Application of Eddy Current

Magnetic Levitation: It is a repulsive type of levitation finds application in modern high speed Maglev trains to provide frictionless transportation. Changing magnetic flux produced by a superconducting magnet placed on the moving train produces eddy currents on the stationary conducting sheet over which train levitates. The eddy currents interact with the magnetic field to produces forces of levitation.

Hyperthermia Cancer Treatment: Eddy current heating used for tissue heating. Eddy currents induced in the conducting tubings by proximal wire windings connected to a capacitor to form a tank circuit which is connected to a radio frequency source.

Eddy Current Braking: Kinetic energy converted into heat due to eddy current losses finds numerous applications in industry :- Braking of trains.

- Braking of a roller coaster.

- Electric saw or drill for its emergency shut-off.

Induction Heating: It is the process of electrically heating a conducting body by inducing eddy currents in it using high frequency electromagnet. Its main applications are induction cooking, induction furnace used to heat metals to their melting point, welding, brazing etc.

Eddy Current Adjustable Speed Drives: With the help of feedback controller an eddy current coupled speed drive can be achieved. It finds applications in metal forming, conveyors, plastic processing etc.

Metal Detectors: It detects present of metals inside rocks, soils etc. with the help of eddy current induction in the metal if present.

Data Processing Applications: Eddy current non destructive testing used in investigating composition and hardness of metal structures.

Speedometer and Proximity Sensing Applications

Comments

Post a Comment